- small screw,micro fastener,mini screw

- 0756-8586520

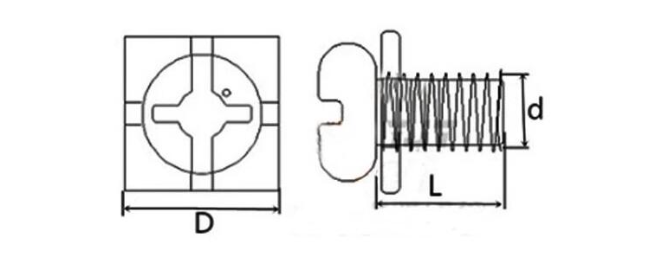

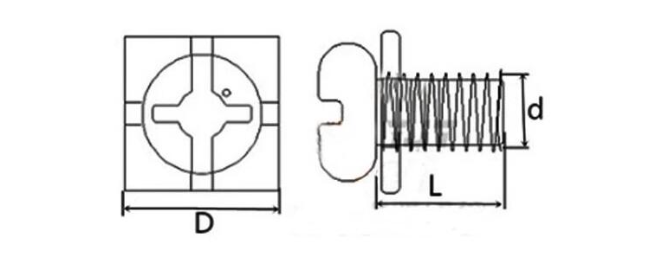

Nickel-plated pan head cross with square pad combination screws M3 switch terminal screws

- Product description:The core competitiveness of nickel-plated pan-head Phillips combo screws with square washers stems from their "1+1>2" structural design — integrating pan-head screws, Phillips drives, and square washe

I. Structural Design: Synergistic Advantages of "Integrated Combination"

The core competitiveness of nickel-plated pan-head Phillips combo screws with square washers stems from their "1+1>2" structural design — integrating pan-head screws, Phillips drives, and square washers into an organic whole. Each component not only fulfills its independent function but also collaborates to enhance overall performance, which can be broken down into three key parts:

1. Pan Head: Balancing "Force-Bearing Area" and "Convenient Inspection"

Unlike the "invisibility" of countersunk heads, the pan head features a raised circular shape with a flat top and curved side transitions. The core advantages of this structure lie in "uniform force distribution" and "visual inspection": On one hand, the raised head increases the contact area with the workpiece surface, dispersing fastening pressure over a larger region to prevent deformation or damage to soft substrates (such as plastic and thin metal sheets) caused by excessive local pressure. On the other hand, the exposed head allows operators to visually check if the screw is tightened without tools — a feature particularly useful for rapid quality inspection in mass assembly scenarios. For example, during the assembly of plastic-cased equipment, the exposed pan head enables workers to identify loose screws at a glance, reducing the risk of missed inspections. Meanwhile, the curved sides prevent scratches to operators or snags on cables from sharp edges.

2. Phillips Drive: High Compatibility, Lowering Operation Threshold

Consistent with countersunk screws, the Phillips drive is the core driving method for this combo screw, but its value is more prominent in the "combined" structure. Compared to slotted drives, the Phillips drive offers stronger torque transmission and is less prone to "cam-out" (damage to the drive slot due to screwdriver slippage). It is also compatible with a variety of tools, including manual screwdrivers, electric bits, and pneumatic screwdrivers, making it highly efficient for both home users’ manual repairs and factory automated assembly. In the integrated design, the standardized driving feature of the Phillips drive further simplifies operations — no additional tool adjustments for the washer are needed; aligning with the Phillips slot enables simultaneous fastening of the screw and washer. This avoids the inconvenience of placing washers separately, especially in narrow spaces, significantly improving installation efficiency.

3. Square Washer + Integrated Connection: Eliminating Pre-Assembly, Enhancing Stability

The integrated design of the "square washer" and "screw shank" is the most innovative feature of this type of screw. In traditional fastening operations, washers must first be sleeved onto the screw shank before installation — a step that not only adds complexity but also risks "washer failure" due to displacement. In contrast, the square washer of the combo screw is fixedly attached to the shank via welding or stamping, enabling "one-step installation" without separate washer handling. Compared to round washers, the square washer’s rectangular shape offers a "rotation-proof" advantage: When the screw is tightened, the sides of the square washer fit against grooves or edges on the workpiece surface, preventing the washer from shifting with the screw’s rotation. This ensures the washer remains in the correct position, effectively dispersing pressure and protecting the substrate. For instance, when securing thin metal sheets, the square washer can lock tightly against the sheet’s edge, preventing washer slippage due to vibration and thus avoiding screw loosening, which enhances long-term connection stability.

II. Nickel-Plating Process: Endowing Triple Benefits of "Corrosion Resistance + Texture + Compatibility"

The nickel-plated layer is not merely a surface decoration but a key process that enhances the combo screw’s performance across three dimensions — "durability," "compatibility," and "aesthetics" — tailored to its application scenarios. Through electroplating, a uniform nickel layer (5-15 microns thick) is formed on the screw (including the square washer), enabling it to withstand complex environments such as humidity and mild corrosion while meeting the dual demands for appearance and performance in electronics and home applications.

1. Corrosion & Rust Resistance: Withstanding Multi-Environmental Erosion

The "integrated" structure of the combo screw means the joint between the washer and shank is prone to corrosion. However, the nickel layer forms a complete "protective barrier," isolating the substrate from air and moisture. Ordinary carbon steel combo screws exposed to kitchen fumes, bathroom humidity, or mild acid-base environments in industrial workshops are susceptible to thread rust and loosening at the washer-shank joint. The chemical stability of the nickel layer effectively slows this process: For example, nickel-plated screws used to secure washing machine bases maintain a rust-free state in long-term humid conditions, preventing increased equipment vibration due to corrosion. Similarly, nickel-plated screws inside outdoor distribution boxes resist corrosion from rain splashes, extending their service life by 3-5 times.

2. Conductive Compatibility: Meeting Special Needs of Electronic Scenarios

In electronic equipment assembly, combo screws not only fasten components but may also assist in conduction or grounding. Nickel exhibits better conductivity than ordinary carbon steel, so the nickel layer improves the screw’s conductive efficiency, reduces contact resistance, and prevents local overheating caused by excessive resistance. For example, when securing internal metal brackets in routers, nickel-plated combo screws simultaneously achieve "bracket fastening" and "grounding conduction," ensuring timely electrostatic discharge from the device. In LED display module connections, the nickel layer also aids signal transmission, reducing signal loss and improving display stability. Additionally, the smooth surface of the nickel layer minimizes fluctuations in contact resistance, ensuring stable conductivity during long-term use.

3. Aesthetic Texture: Adapting to Aesthetic Demands of Home & High-End Equipment

The nickel layer presents a uniform silvery-white luster with a soft texture that resists fading. Compared to black oxide or galvanizing processes, it is better suited for scenarios requiring high aesthetic standards. In high-end home assembly — such as Nordic-style metal furniture or hardware connections for wooden storage cabinets — the silvery-white tone of the nickel-plated combo screw complements metal and wood textures. The exposed pan head and square washer not only preserve overall aesthetics but also serve as decorative details. In securing precision instrument casings, the uniform luster of the nickel layer enhances the equipment’s premium feel, avoiding negative impacts on overall product quality from rough-looking screws.

III. Application Scenarios: Precise Coverage from "Light Assembly" to "Daily Use"

The "integrated" design and nickel-plated performance of the combo screw make it highly advantageous in scenarios requiring "efficient assembly," "stable connections," and "resistance to mild corrosion." Its core applications fall into three categories:

1. Home & Appliance Sector: Convenient Installation, Adapting to Soft Substrates

In home assembly, this combo screw is a "DIY-friendly" choice. For securing drawer slides in wooden furniture or metal hanging rods in wardrobes, the combination of the pan head and square washer disperses pressure to prevent wood cracking. For connecting plastic storage cabinet shelves, the integrated design eliminates the need to place washers separately, allowing home users to complete installation quickly without professional tools. In the appliance sector, for securing the casings of washing machines and air conditioners or internal metal brackets in microwaves, the nickel layer’s corrosion resistance handles humid internal environments, while the square washer’s rotation-proof design prevents screw loosening from equipment vibration. For example, when fixing air conditioner indoor unit mounting plates, the square washer of the combo screw locks tightly into the plate’s grooves, ensuring long-term stability of the unit and reducing noise.

2. Electronics & Light Equipment Sector: Efficient Assembly, Balancing Conductivity

Mass assembly of electronic equipment demands high efficiency and precision, and the combo screw’s integrated design significantly speeds up production lines. For example, in securing mobile phone charger casings, automated equipment can directly grip the combo screw for installation without additional washer feeding mechanisms. In securing internal plastic gears in printers, the efficient driving of the Phillips slot and pressure dispersion of the square washer prevent damage to plastic components. In light industrial equipment — such as securing the casings of small water pumps or handles of power tools — the nickel layer’s corrosion resistance handles oil and moisture during use, while the combined design reduces assembly steps and lowers production costs.

3. Outdoor & Mild Corrosion Scenarios: Stable Durability, Reducing Maintenance

In outdoor mild corrosion scenarios, the nickel layer and integrated structure of the combo screw reduce maintenance needs. For example, in connecting aluminum alloy brackets of outdoor awnings, the nickel layer resists corrosion from rain and UV rays, while the square washer’s rotation-proof design ensures long-term bracket stability. In securing garden light bases, the combo screw eliminates the need for frequent checks on washer displacement, reducing outdoor maintenance difficulty. Additionally, in securing plastic components in automotive interiors — such as dashboard trim panels and door interior panels — the nickel-plated combo screw adapts to mild humidity inside vehicles and improves production efficiency through convenient installation.

IV. Installation & Selection: Avoiding Mistakes to Maximize Fastening Effect

Despite the ease of operation of the nickel-plated pan-head Phillips combo screw with square washer, correct installation methods and selection logic are critical to ensuring fastening effectiveness. Key points include:

1. Installation Tips: Focus on "Pressure Dispersion" and "Torque Control"

Two core details require attention during installation: First, "substrate compatibility" — this screw is better suited for soft or thin substrates (plastic, wood, thin metal sheets). If used on hard, thick metal plates, it may fail to drive or deform the square washer; specialized hard combo screws should be used instead. Second, "torque control" — when using power tools, torque should be adjusted based on substrate hardness. For example, over-tightening plastic components may cause cracking, so low torque and slow tightening are recommended until the pan head and square washer fit tightly against the substrate. For wooden components, torque can be slightly increased, but over-tightening that damages wood fibers should be avoided. Additionally, ensure the square washer fits fully against the substrate surface to prevent uneven pressure distribution from tilted washers.

2. Selection Logic: Matching Based on "Specifications" and "Scenarios"

Three key parameters should be considered when selecting the screw: First, "specifications," including nominal diameter (e.g., M3, M4, M5), screw length (selected based on substrate thickness to ensure full thread engagement and tight 贴合 of the square washer), and square washer size (washer side length is typically 2-3mm larger than the pan head diameter to ensure effective pressure dispersion). Second, "corrosion environment" — for humid or mild corrosion scenarios (e.g., bathrooms, outdoors), select products with a nickel layer thickness ≥8 microns for enhanced corrosion resistance. Third, "load requirements" — for applications requiring high tensile strength or resistance to vibration, choose higher-precision "machine-thread-grade" combo screws to avoid loosening from thread errors. For example, to secure a 10mm-thick plastic sheet, the M4×12mm combo screw is suitable to ensure sufficient thread depth and effective pressure dispersion by the square washer. For outdoor light installation, prioritize specs with a nickel layer thickness ≥10 microns to withstand outdoor corrosion.

V. Conclusion: "Small Innovation, Great Value" of Combined Design

Though seemingly simple, the nickel-plated pan-head Phillips combo screw with square washer solves the "low efficiency" and "easy displacement" issues of traditional separate fastening through its "screw + square washer" integrated design. Leveraging the nickel-plating process, it also balances "corrosion resistance," "conductivity," and "aesthetics." Without complex structures, it optimizes the fastening experience in details — from home users’ DIY projects to factory mass assembly, from daily fixing of home appliances to precision connections in electronic equipment. Understanding its "combinatorial synergy" design logic and mastering installation/selection methods allows this "combo screw" to maximize its value in various scenarios, serving as a "reliable assistant" for improving fastening efficiency and stability.